一.Product Features |

1 | Product name | ZKSJ DC80E DC Pump |

|

2 | Model No. | DC80E DC pump |

3 | Weight: | 2.1kg |

4 | Life span: | ≥30000h |

5 | Waterproof Grade: | IP68 |

6 | Color: | Black |

7 | EPL: | Meet ROHS requirements |

8 | Material of pump shell: | PPS+30%GF |

9 | Noise class: | ≤40dB |

10 | Leakproofness: | ≥1MPa |

11 | Insulation grade: | H Grade(180°) |

12 | Working principle: | Centrifugal pump |

13 | Application | Cooling circulation system, supercharging system |

二.Range of application |

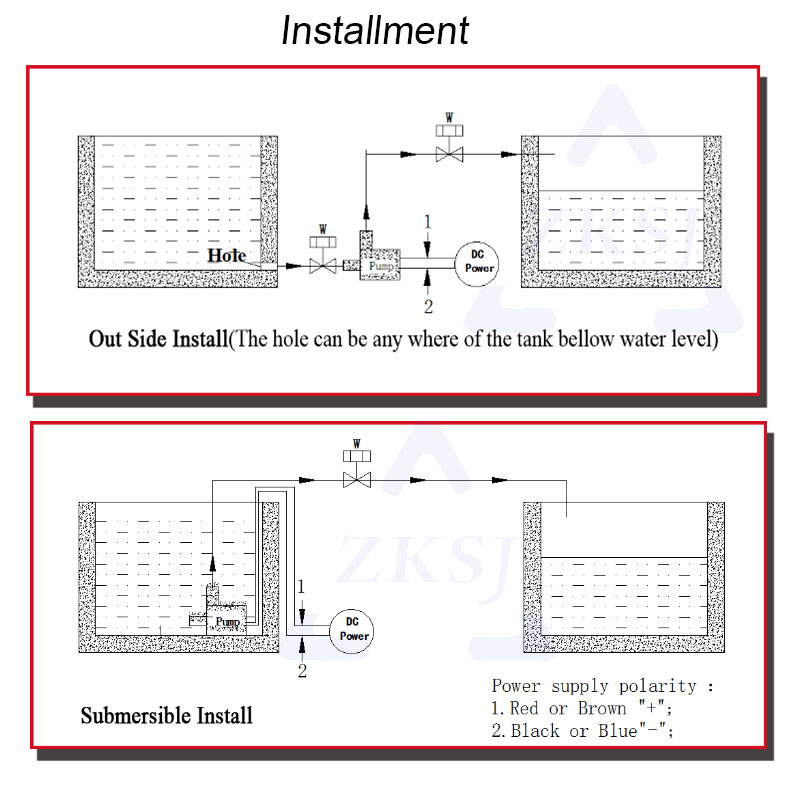

1 | Ambient Temperature | 3-phase controller inside for non-submersible/controller outside for submersible |

2 | Liquid Type | Oil, water, and other liquids |

3 | Liquid Temperature | -30°—100° 3-phase controller inside for non-submersible /controller outside for submersible |

4 | Power | DC Power Supply |

三.Electrical parameters (only for reference) |

1 | Product model: | DC80E-1260PWM DC80E-1260VR DC80E-1260S | DC80E-2475PWM DC80E-2475VR DC80E-2475S | DC80E-24100PWM DC80E-24100VR DC80E-24100S | DC80E-36100PWM DC80E-36100VR DC80E-36100S | PWM:PWM speed(50-800HZ/ 5V) VR:0~5V/Potentiometer speed S:constant rotational speed |

2 | Rated Voltage | 12V DC | 24V DC | 24V DC | 36V DC |

|

3 | operating voltage range: | 5-12V | 5-28V | 5-28V | 5-40V | Within this range, the pump can work normally |

4 | Rated current: | 5.4A(6.6A) | 3.5A(4.2A) | 5.4A(6.3A) | 3.6A(4.2A) | Closed outlet current (open pumping current) |

5 | Power: | 65W(80W) | 84W(100W) | 130W(150W) | 130W(150W) | Closed outlet power (open pumping power) |

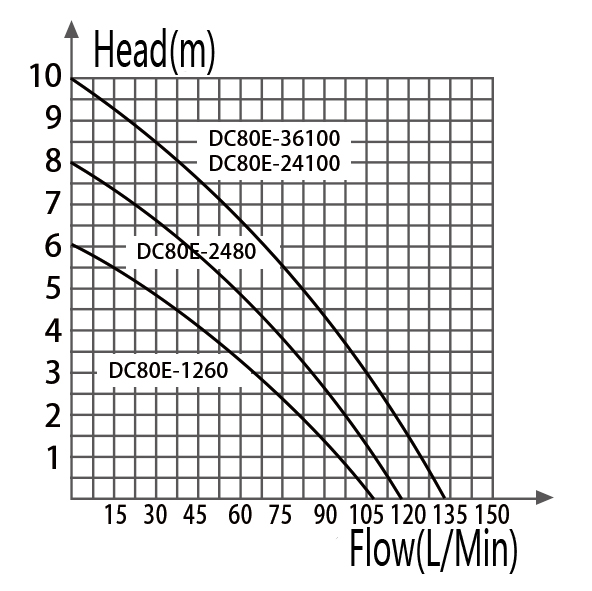

6 | Max. Flow: | 6500L/H | 7000L/H | 8000L/H | 8000L/H | The flow of water when there is no takeover |

7 | Max.Head | 6M | 7.5M | 10M | 10M | Static head |

8 | Minimum input power supply: | 12V-7A | 24V-5A | 24V-7A | 36V-5A |

|

四.Additional function instructions |

1 | K-jam protection | When the impurity enters the rotor chamber, the rotor stops running, and the pump stops running as well. |

2 | Dry run protection | The pump will stop working when no enough water inside pump. |

3 | Overloading protection | When the voltage is unstable or exceeds the rated power, the pump will stop working. |

4 | Power reverse connection | Wrong connection of the power supply(positive and negative), the water pump will stop running, and then re-connected, can work normally. |

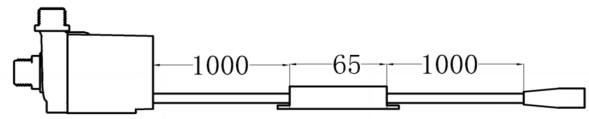

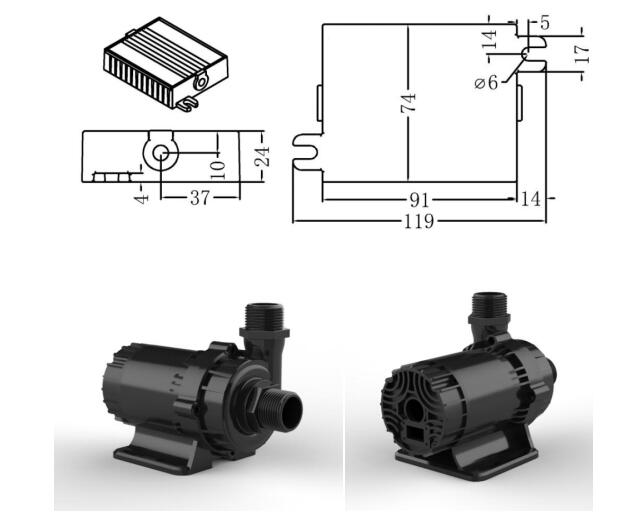

| Built-in pump driver |  | Suitable for non - diving installation, medium below 60 degrees |

| The pump driver is external |  | Submersible installation, high temperature resistance |

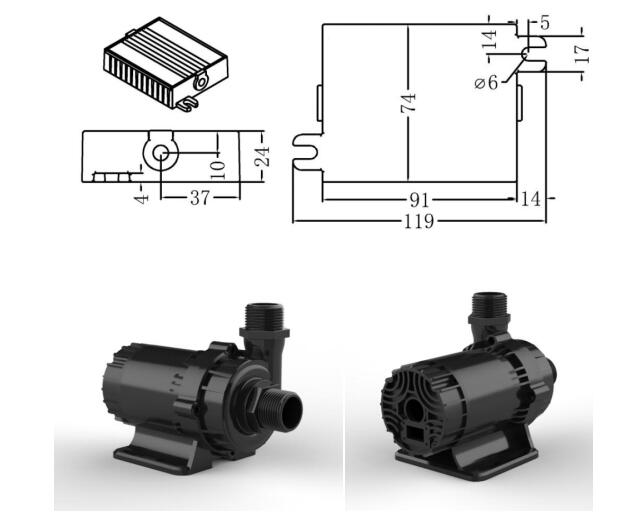

五.Installation Drawing

Notice: The pump is not self-priming pump. When install, please make sure there is enough water in pump gland. Meanwhile, the pump must be installed below the liquid level in the tank.

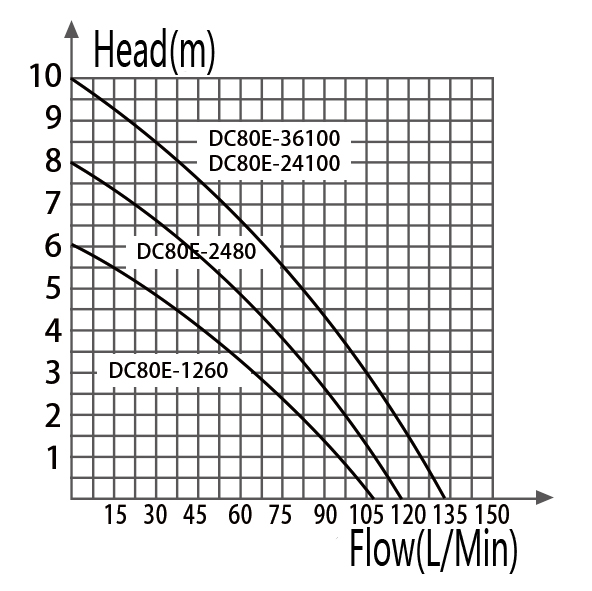

六.Head flow curve

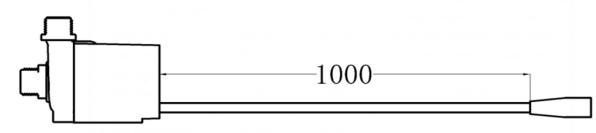

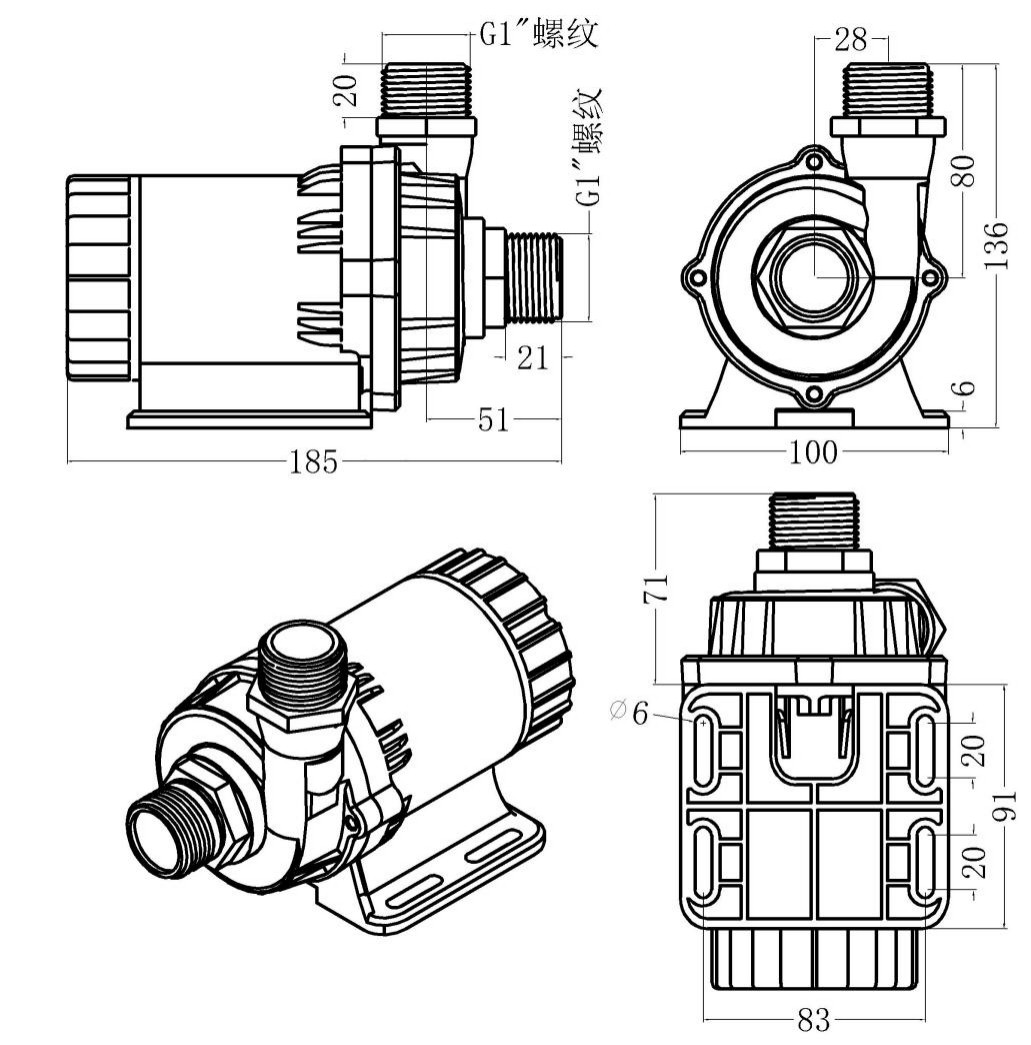

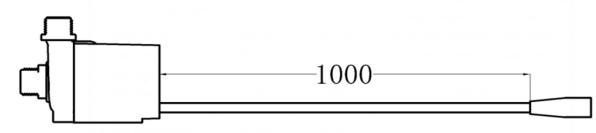

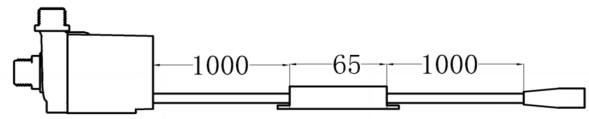

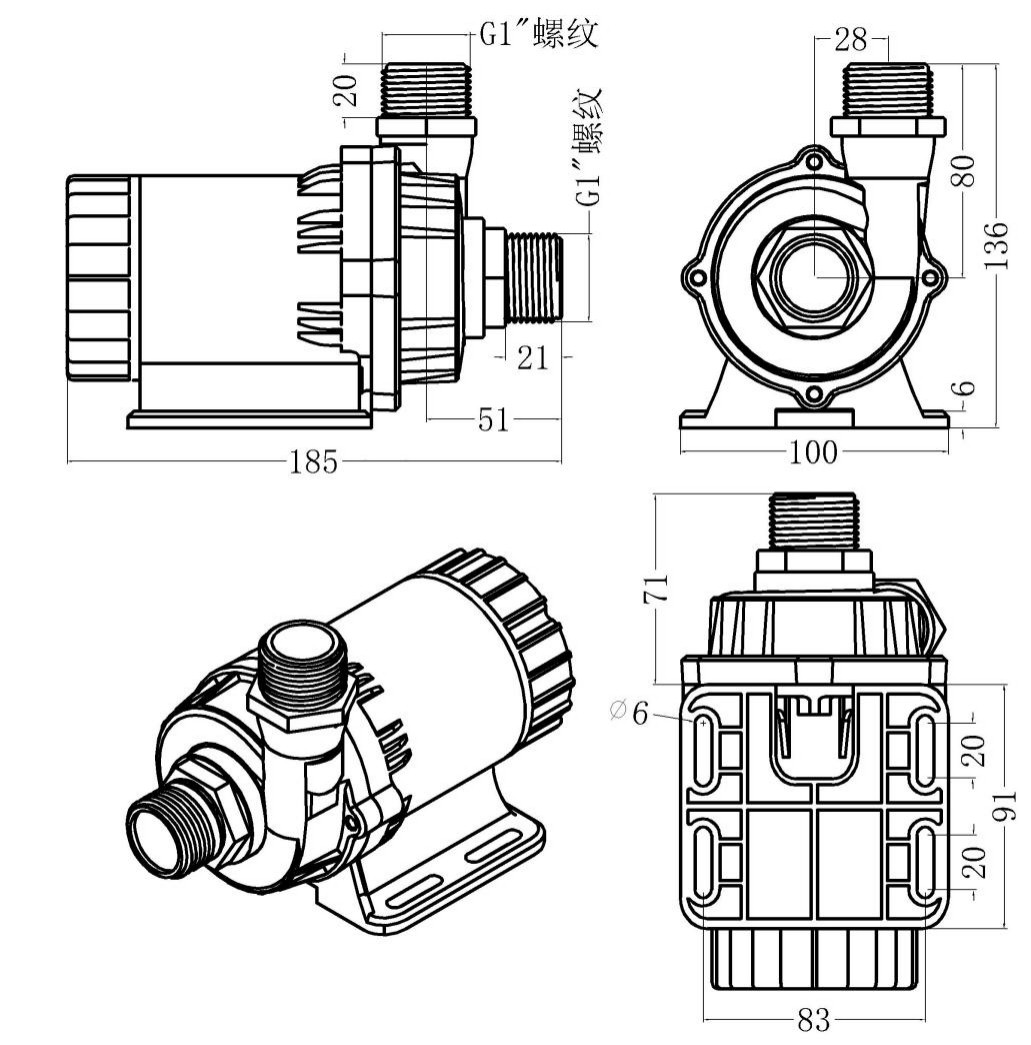

七.Dimension and appearance

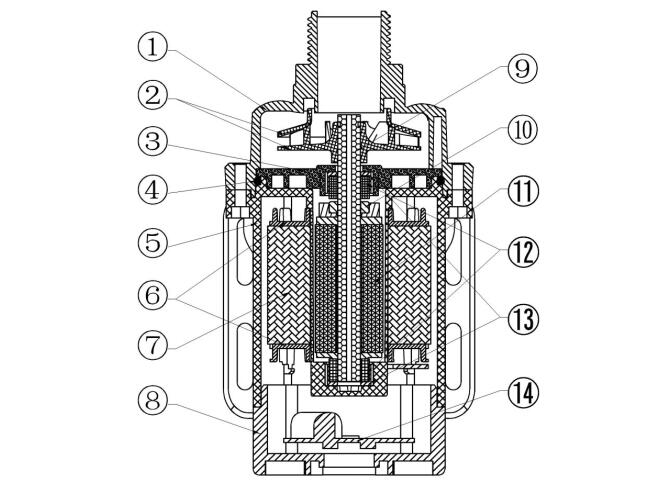

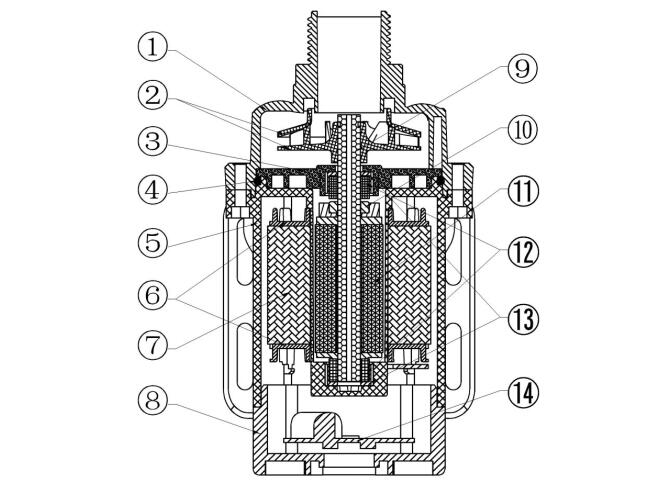

八.BOM

Bill of Material |

No. | Description | Specification | Qty | Material | No. | Description | Specification | Qty | Material |

1 | DC80E Cover | PPS | 1 | PPS | 13 |

|

|

|

|

2 | O-ring | 50*55*2.5 | 1 | EPDM | 14 |

|

|

|

|

3 | DC80 Body | PPS | 1 | PPS | 15 |

|

|

|

|

4 | 80 Stator | 50*27*25*6P*H25 | 1 | Iron Core | 16 |

|

|

|

|

5 | 80 3-phase insulated sleeves | PA66+30% | 1 | Nylon | 17 |

|

|

|

|

6 | DC80 Back Cover | PPS | 1 | PPS | 18 |

|

|

|

|

7 | 80 Ferrite closed impeller | PA66+30% | 1 | Nylon | 19 |

|

|

|

|

8 | Ceramic shaft sleeve | H3.5*8*3.7 | 1 | Zirconia | 20 |

|

|

|

|

9 | 80 Ceramic shaft | 40*3.7 | 1 | Zirconia | 21 |

|

|

|

|

10 | Graphit sleeve | H26.8*7*3.72 | 1 | Graphit | 22 |

|

|

|

|

11 | Ferrite magnet | 28*24*12.8 | 4 | Magnet | 23 |

|

|

|

|

12 |

|

|

|

| 24 |

|

|

|

|

九.Failure and maintenance

Failure and maintenance |

| Failure | Reason | Solutions |

1 | Large current and small flow | Impurities in the rotor | injection water from the outlet to clean the inside |

2 | stop working and current is unstable | The rotor is stuck | Clean foreign matter makes rotor stuck |

Stop working and short circuit | Control board is damaged | Change a new pump |

Stop working and no current | Check the power cord | Reconnect the power |

3 | Big noise | Impurities in the pump | Clean the impurities |

Air in the pump and can’t get out | Put the outlet upwards, makes water no air |

no water in the pump, dry run | Make sure enough water inside |

十.Notice

Notice

1. It is strictly forbidden to use liquids with impurities greater than 0.35mm and ceramic or magnetic particles.

2. If it is not used for long time,make sure water inside pump before power on.

3. Do not let pump dry run

4. If not used for long time, please make sure cord connection correctly.

5. If use in low temperature environment, please make sure the water won’t be frozen or thick.

6. Please check if there is water on connection plug, and clean it before use.